ANAND IMPEX

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ANAND IMPEX

Conveyorised Plants Compact Plants For Auto And Small Parts

Compact plant are designed for small parts like two wheeler press components, pressure die castings, tubular components multiple loops of conveyor are take iside the compacted oven booths may be single side coating with auto indexing.

These plants are typically suitable to fit in small shop floor spaces, mexxanine floor etc.

Complete automation is also possible for standardised parts.

We have supplied several plants for fan industry, two wheeler auto parts like fork, yoke, mud guard etc.

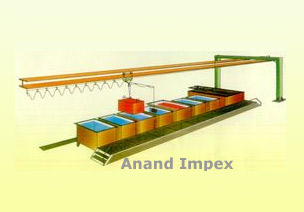

Conveyorised Plant Aluminium Extrusion Coating Plants

Anand Impex specialises in providing turnkey solution to any surface finishing need.

Complete conveyorised plants for liquid and powder coating with either liquid or powder option are supplied Conveyor in this case has a dual speed.

For job coaters conveyorised plant with oven having batch curing facility from one end and conveyor from another end are provided.

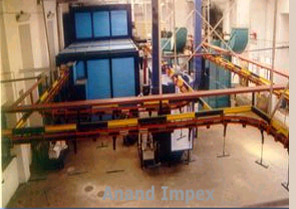

Conveyorised Plant Liquid And Powder

Anand Impex specialises in providing turnkey solution to any surface finishing need.

Complete conveyorised plants for liquid and powder coating with either liquid or powder option are supplied Conveyor in this case has a dual speed.

For job coaters conveyorised plants with oven having batch curing facility from one end and conveyor from another end are provided.

Conveyorised Plant Completely Automated Plants

A Turnkey solution for complete Automation with Online Spray Phosphating, Dry Off Oven, Automatic Powder Application with Reciprocators, Auto suns with Touchup provision and Conveyorised Powder Curing is provided by Anand Impex.

Only loading & unloading of articals on conveyor is munal in this case.

Conveyorised Plant Turnkey Paint Shop

Anand Impex specialises in providing turnkey solution to any surface finishing need.

Turnkey paintshops for liquid painting are supplied with ARP, paint booths with automatic paint sludge removal, flash off zones.

Automatic object sensing for auto changeover of oven temperature can be provided. This different components like silencers with 200 deg. and MFN parts with 130 deg. can be painted in same plant in continuation.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

60993.jpg)

60994.jpg)

60995.jpg)